Umgubo wesinyithi wenza i-hydraulic press

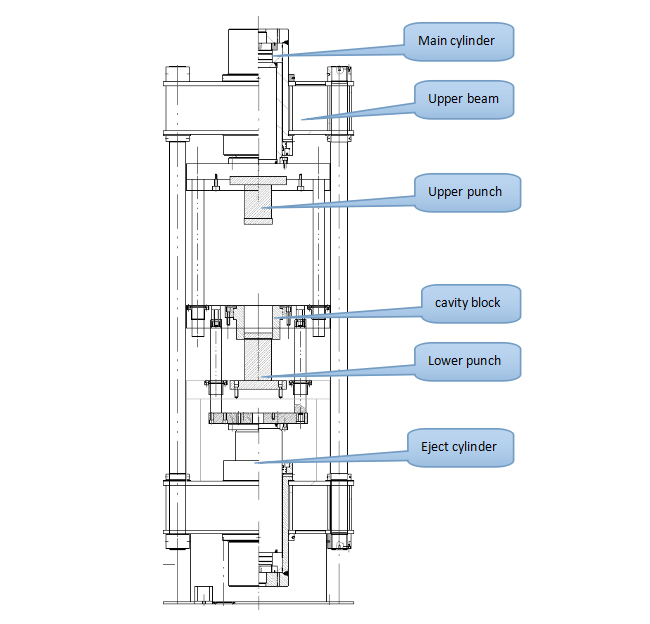

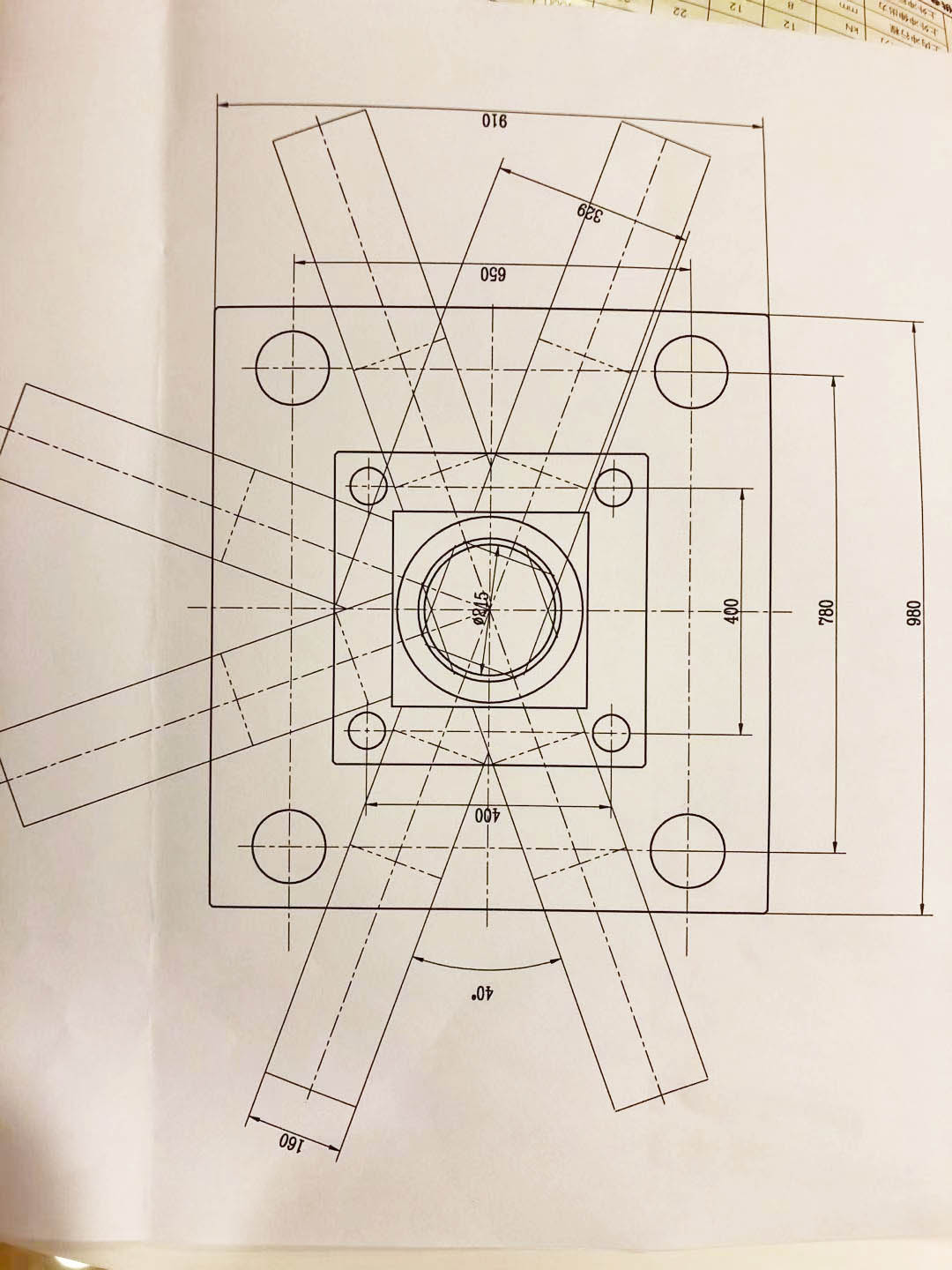

Isakhelo sokungunda

I-1) Isiseko sokubumba senziwe ngokukodwa kwi-40Cr kunye ne-45 # yensimbi ngokubumba, ukujika kunye nokugaya okulungileyo ukuqinisekisa ukuba insimbi eyaneleyo kunye nokuchaneka okufanayo.Umphezulu wesikhokelo wamkela ulwahlulo lwezinto zokukhusela umphezulu kwi-abrasion, njengemikhono yesikhokelo sobhedu.Ndikunye noCr.

I-2) Ingxenye ephezulu ye-mold frame yi-punch eyodwa ephezulu, kwaye i-punch ephezulu igxininiswe ngokuthe ngqo kwi-slide ye-punch ephezulu;ukungunda kowasetyhini kugxininiswe kwitemplate engalunganga, kwaye zombini ukunyanzelwa okusebenzayo okudadayo kunye nokunyanzelwa kokunyanzelwa okudadayo kwenziwa kwinkqubo yokucinezela.Ukukhethwa ngokungenamkhethe, "umgubo", ukunyanzeliswa okudadayo, ukulibaziseka ukubamba uxinzelelo, ukulibaziseka koxinzelelo, njl njl.Xa uhambisa umgubo, iimolds ezimbi ezidadayo eziphezulu kunye nezantsi zidada ngokuhambelanayo kunye ne-punch ephezulu.

3) Indlela yokudiliza ine-demolding jikelele kunye nokukhusela ukuchithwa kokukhethwa;i-mold female kunye ne-undershoot ine-demoulding ngaxeshanye kwaye i-mold ye-female itsalwa phantsi ukuze ikhulule ngokuthe ngqo i-mold, kunye nokukhululwa kwe-mold esebenzayo ye-mold ye-female iluncedo ukukhusela ngcono imveliso ukuba yonakaliswe lula.

I-4) Ubude bokutya, ukuphakama kwemveliso kunye nokudiliza indawo sebenzisa inzwa yokufuduka ukuze ibone indawo kunye neprogram ye-PLC echanekileyo yokulawula, kunye nomda wesixhobo somatshini.

5) Isixhobo esidibeneyo esingeyiyo isinyithi sifakwe kwindawo edibeneyo phakathi kwepleyiti edadayo kunye nebhloko yomgodi wesakhelo sokungunda, kwaye into edibeneyo engeyiyo isinyithi ibekwe yodwa kwisihlangu sokutya kunye nehopper yokugcina, kwaye zonke iinxalenye zetsimbi zikho. ungadibanisi nomgubo wezinto ezikrwada.

Inkqubo yokondla

1.Inkqubo yokutya iya kuba neehopper ezi-6, kwaye ihopha nganye iya kulayisha imathiriyeli ekrwada eyahlukileyo.

2.I-hopper inokujikeleziswa, kwaye itywinwe kakuhle.

3.Ukulayishwa ngokuzenzekelayo kwemathiriyeli ekrwada, rhoqo ngemivumbo emi-5-10.

4.Ubungakanani bokusebenza beHopper bunokusetwa kwi-HMI, 1,2,3 …10 ,isebenza kunye.

I-5.6 i-hoppers enkulu iya kufakwa phezulu kumatshini, i-hopper nganye inokulayisha i-15 Kg yomgubo.

Intsika

Iikholamu zesikhokelo (iintsika) ziya kwenziwaC45 eshushu forging steelkwaye ube nobukhulu obuqinileyo be-chrome obuyi-0.08mm.Kwaye wenze ukuqina kunye nokuthomalalisa unyango.

ImiGangatho yokuVelisa

JB/T3818-99《Iimeko zobugcisa zoshicilelo lwe-hydraulic》

GB5226.1-2002《Ukhuseleko koomatshini-oomatshini kunye nezixhobo zombane-Icandelo 1: Iimfuno zobugcisa ngokubanzi》

GB/T 3766-2001《Iimfuno zobugcisa ngokubanzi kwiinkqubo zamanzi》

GB17120-97《Cinezela iimfuno zobugcisa zokhuseleko koomatshini》

JB9967-99《Umda wengxolo yomatshini weHydraulic》

UMzimba oPhambili

Uyilo lomatshini wonke lwamkela uyilo lokuphucula ikhompyuter kwaye luhlalutye ngento enomda.Amandla kunye nokuqina kwezixhobo zilungile, kwaye imbonakalo ilungile.Onke amalungu adityanisiweyo omatshini adityaniswe ngentsimbi ekumgangatho ophezulu we-Q345B ipleyiti yentsimbi, edityaniswe ngekhabhoni diokside ukuqinisekisa umgangatho wokuwelda.

Isilinda

| Amacandelo | Findalo |

| Umgqomo wesilinda |

|

| I-Piston Rod |

|

| Amatywina | Yamkela umsesane wokutywina womgangatho we-NOK waseJapan |

| Ipiston | Ukukhokelwa ngokutyalwa kobhedu, ukuchasana kakuhle kokugqoka, ukuqinisekisa ukusebenza kwexesha elide le-cylinder |

Inkqubo yeServo

1.Servo System Ukuqulunqwa

2.Izinto eziluncedo zeServo System

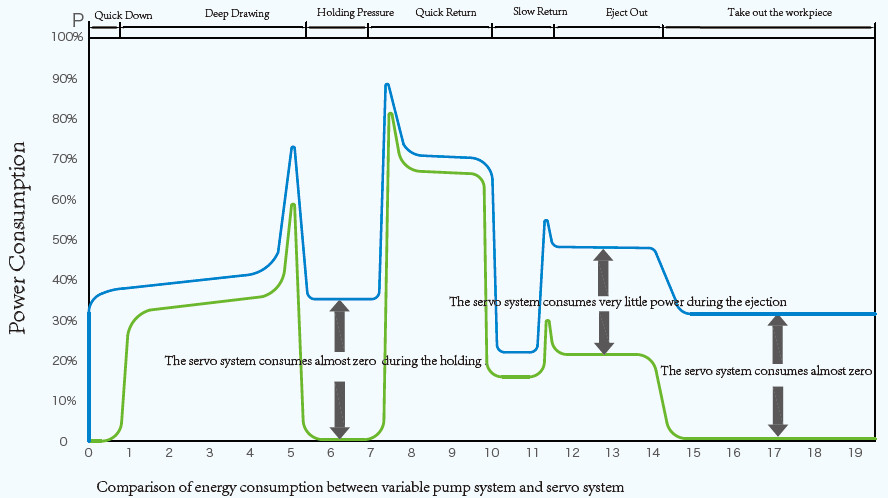

Ukonga amandla

Xa kuthelekiswa nenkqubo yempompo eguquguqukayo yemveli, inkqubo yempompo yeoli ye-servo idibanisa iimpawu zolawulo lwesantya esingena nyathelo se-servo motor kunye neempawu ezizilawulayo zoxinzelelo lweoyile yempompo yeoli ye-hydraulic, ezisa amandla amakhulu okonga, kunye namandla.izinga lokonga lingafikelela kuma-30% -80%.

Esebenzayo

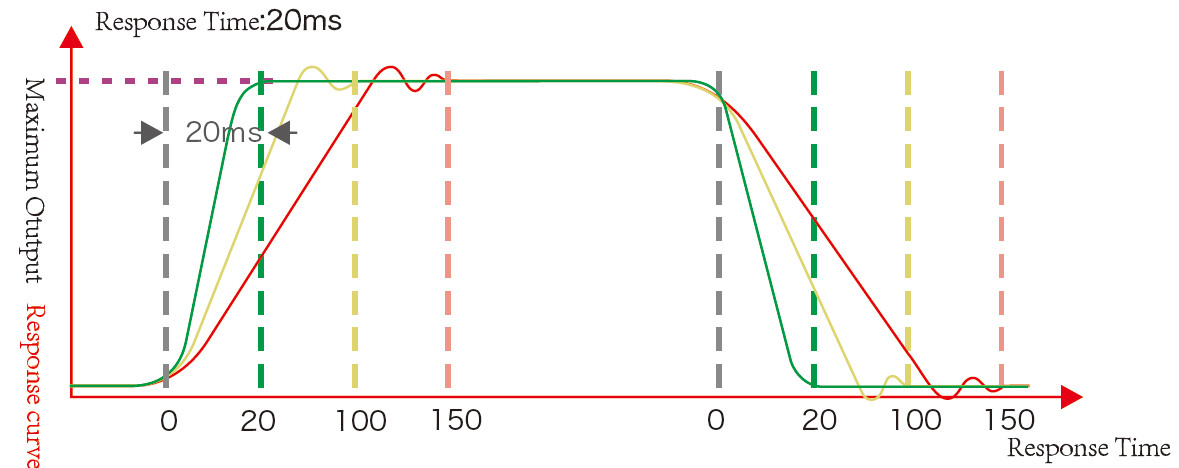

Isantya sokuphendula sikhawuleza kwaye ixesha lokuphendula lifutshane njenge-20ms, eliphucula isantya sokuphendula kwenkqubo ye-hydraulic.

Ukuchaneka

Isantya sokuphendula ngokukhawuleza siqinisekisa ukuchaneka kokuvula kunye nokuvala, ukuchaneka kwendawo kunokufikelela kwi-0.1mm, kwaye umsebenzi okhethekileyo wokumisa ukuchaneka unokufikelela.±0.01mm.

Ukuchaneka okuphezulu, impendulo ephezulu yemodyuli ye-algorithm ye-PID iqinisekisa uxinzelelo lwenkqubo ezinzileyo kunye noxinzelelo loxinzelelo olungaphantsi± 0.5 ibha, ukuphucula umgangatho wemveliso.

Ukhuseleko lokusingqongileyo

Ingxolo: Ingxolo eqhelekileyo yenkqubo ye-hydraulic servo yi-15-20 dB ephantsi kunompompo oguquguqukayo wokuqala.

Ubushushu: Emva kokuba inkqubo ye-servo isetyenzisiwe, ukushisa kweoli ye-hydraulic kuncitshiswa ngokubanzi, okwandisa ubomi be-hydraulic seal okanye ukunciphisa amandla opholileyo.

Isixhobo soKhuseleko

Ifoto-yoMbane woKhuseleko loMbane ngaphambili nangasemva

Ukutshixa isilayidi kwi-TDC

Ukuma kokuSebenza kwezandla ezimbini

I-Hydraulic Support Insurance Circuit

Ukukhuselwa komthwalo ogqithisileyo: iValve yoKhuseleko

I-Alarm yeNqanaba lolwelo: Inqanaba le-oyile

Isilumkiso sobushushu be-oyile

Indawo nganye yombane inokhuseleko lokugcwala

Iibhloko zokhuseleko

Amandongomane okutshixa anikezelwe kwiindawo ezishukumayo

Zonke izenzo zoshicilelo zinomsebenzi wokhuseleko onxibelelanayo, umzekelo, itafile eshukumayo ayinakusebenza ngaphandle kokuba umqamelo ubuyela kwindawo yokuqala.Isilayidi asikwazi ukucinezela xa itheyibhile eshukumayo icinezela.Xa kusenzeka ungquzulwano, i-alam ibonisa kwiscreen esichukumisayo kwaye ibonise ukuba yintoni impixano.

Inkqubo yeHydraulic

I-1.Itanki ye-oyile isetiwe ngenkqubo yokucoca ngenkani yokupholisa (isixhobo sokupholisa ipleyiti yeshishini, ukupholisa ngamanzi ajikelezayo, ubushushu be-oyile≤55℃, qiniseka ukuba umatshini unokucofa ngokuthe chu kwiiyure ezingama-24.)

I-2.Inkqubo ye-hydraulic ithatha inkqubo edibeneyo yokulawula i-cartridge valve kunye nesantya sokuphendula ngokukhawuleza kunye nokusebenza kakuhle kokuhanjiswa.

3.Itanki yeoli ixhotyiswe ngesihluzo somoya ukunxibelelana ngaphandle ukuze kuqinisekiswe ukuba ioli ye-hydraulic ayingcoliswa.

I-4.Ukudibanisa phakathi kwe-valve yokuzalisa kunye ne-tank ye-fuel isebenzisa i-flexible joint ukuthintela ukungcangcazela ukuba kungadluliswa kwi-tank ye-fuel kunye nokusombulula ngokupheleleyo ingxaki yokuvuza kweoli.